The 3D-printing process was developed as part of the National Center of Competence in Research Digital Fabrication as an interdisciplinary endeavor. The system is meant to work for prefabrication setups and integrates dry-mix material preparation with a multi-component delivery system.

The dry mix is stored in a silo and feeding system, which delivers material to a continuous mixer. Mixing is automatically initiated by a sensor-based control loop that monitors the material level within the pumping unit, ensuring a consistent supply and stable rheology.

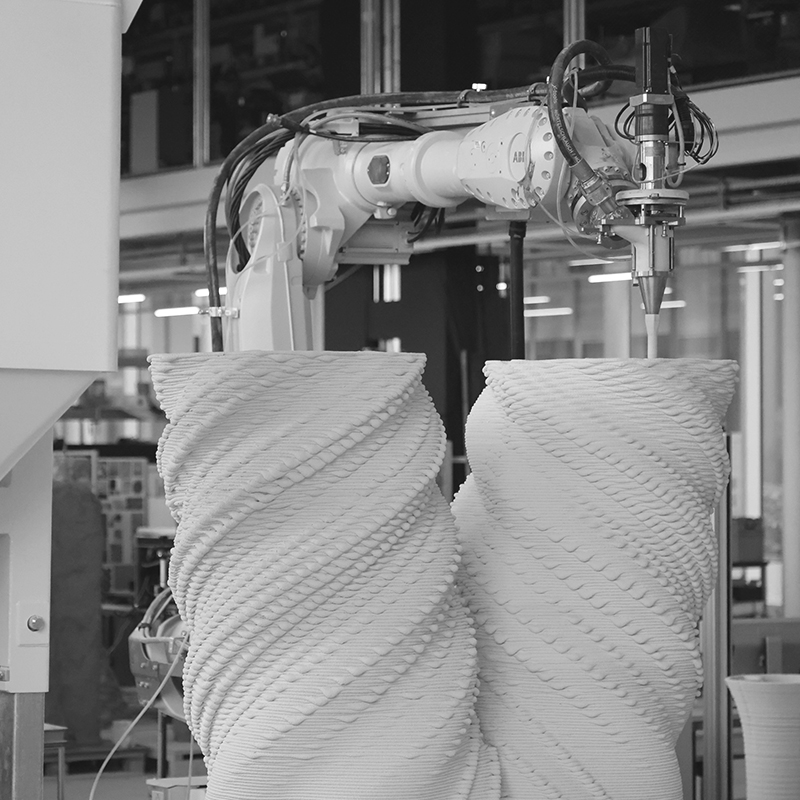

The pumping system operates with three coordinated flow channels: one for the base concrete, and two auxiliary lines for chemical additives—typically an accelerator and a viscosity modifier. These streams converge at the extrusion head, where the components are dynamically blended immediately before deposition. This enables real-time adjustment of setting behavior and print quality during the build.

The extrusion head is mounted on a multi-axis robotic manipulator, which positions and deposits the filament along the predefined print path. The pumps and extrusion system are governed through an integrated numerical control interface, allowing synchronized motion, pressure regulation, and flow-rate management.

Throughout printing, process data—including flow, pressure, and temperature—are continuously recorded and monitored within an open-loop feedback environment. This setup enables fine-tuning of process parameters and provides traceable data for subsequent analysis.

The control framework is implemented through a digital fabrication environment that coordinates robotic motion, material behavior, and system feedback to maintain consistent print performance and material integrity.